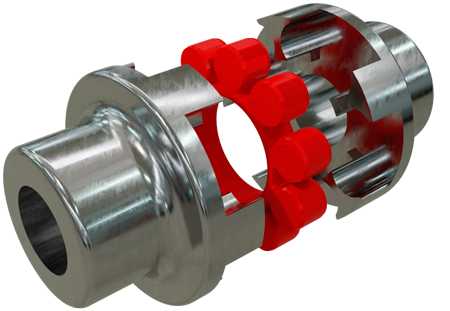

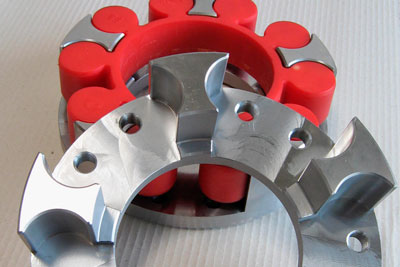

Flexible coupling in a modular system; 13 sizes with diameters from 50 mm to 400 mm; hub–hub, hub–flange, flange–flange and standard attachments can all be combined in each size

Plug-in coupling in two- and three-piece design; flexible ring replaceable by moving a piece of equipment or by loosening a flange-flange connector; power transmission through pressure on stressed elastomers

Physical and technical parameters

- Torque (T) 0.6 Nm to 40,000 Nm

- Speed (n) 15,000 to 1,900 min–1

- Stiffness (C/T) approx. 60

- Permissible ambient temperature: Polyurethane –20°C to +80°C,

Polyurethane (HT) –20°C to +120°C (150°C)

Manufacturing and material

TECMEN couplings in the TMS series are used in cranes, conveyors, trough conveyors, shearers, cutter chain stations, crushers, roller conveyors in mining and general engineering.

Service:

Download a brief profile of the TMS series as well as details of shaft displacement capacity (PDF). If you have any questions, please don’t hesitate to get in touch with us.

The standard questionnaire on design of torsionally flexible couplings you can fill in as form for combustion engine as drive unit or for non combustion drive units or download as pdf. As an additional recommendation we hint on a neat conversion program that’s worth its weight in gold! (Thanks to Josh Madison.)

![[KW] engineering – TECMEN Kupplungen](https://www.kw-tecmen.de/wp-content/uploads/2022/03/cropped-logo_mit_claim_kurven-flaechen_web-rgb-2022.png)